關於約翰遜半自動步槍的雜七雜八【#1】

來自專欄 YGCO

105 人贊了文章

作者: @Sayaka Kanzaki & @Yasouji Ai

未經允許禁止轉載

整理二次大戰中USMC使用武器發現的一些邊邊角角,對於槍械沒有了解,如有錯誤請指出。

通常來說,約翰遜先生的貝姬並不像它的美國同胞M1那麼出名,實際上她也是最容易被遺忘的那位,比如.....你甚至都不能在窯子里找到她。考慮到M1941和M1的關係,她們會經常被放在一起比較,不過更多的時候人們願意把M1和其他參戰國的半自動步槍相提並論。勝負顯而易見.....

約翰遜這邊倒是被普遍認為:.....不管是精度,生產性什麼的,沒一樣比得過M1加蘭德。不過當我們回過頭再看約翰遜先生和他的貝姬的時候,似乎事情不完全是那樣的。出於個人對於海軍陸戰隊的興趣,在整理二次大戰時馬潤裝備相關小冊子時發現約翰遜步槍似乎並不存在那麼明顯的劣勢,或者說它在某些方面甚至比M1更好。

M1和M1941在設計的時候口徑基於現有的.30彈藥,部分原因是利用現有的.30彈藥是要比生產新彈藥更具優勢,那是在一次大戰時期準備好的。這一點約翰遜先生也有所提及, 甚至,約翰遜步槍能夠比加蘭德更好的利用上一次大戰的遺產,它可以直接使用春田式橋夾進行裝載(1).

對於使用舊春田橋夾的必要性,約翰遜先生也做出了解釋。誠然,春田式橋夾有一些問題,但是必須考慮到美國已經生產了兩百萬使用此類橋夾的步槍,這也將稱為約翰遜半自動步槍的優勢(2)。

比起M1,約翰遜步槍在裝填方面有另外優勢,它總能輕鬆的做到讓彈艙里滿載,即不管是使用橋夾還是單發裝填都可以,且子彈數量多於M1(3)。

由於半自動步槍有著更高的射速,約翰遜先生認識到有必要讓半自動步槍的槍管可以快速更換:既然磨損不可避那就讓更換槍管更方便。這也是約翰遜步槍的特點之一,M1無法輕鬆做到像約翰遜步槍那樣可以根據不同的任務調換不同長度的槍管。既然到了這裡,那也就要說一下約翰遜步槍的另一個特點, floating barrel/浮動式槍管,和加蘭德或是之前的春田步槍不同,這使得約翰遜步槍的槍管不與任何護木接觸,無疑是一個有利於提高射擊精度的設計。

來自NRA(National Rifle Association)的技術部門負責人Fred C. Ness也承認這是個好處:

And I did not expect it to be inaccurate just because the barrel moved, although I was told that it would be found so. But we have found that unless a gun is custom-built and very carefully fitted, that is as opposed to production manufacture or factory-made weapons, that it is better to have some freedom between the barrel and its support; it must not be considerable, but some slight freedom. That was brought out before, today, the matter of floating type of fitting between a barrel and the wood and which is what I am discussing.

In all my shooting with the Johnson I had no occasion to change that impression of inherent accuracy. I consider the rifle finely accurate. I like, too, in the design the fact that the springs are away from the hot part of the rifle, which is the barrel; the operating spring, recoil spring, and return spring are back in the back end of the gun. I like the fact very much that the barrels could be removed. In fact, I have fired several .30-caliber barrels, a .270 Winchester caliber barrel, and a 7-millimeter barrel in the same gun, by simply interchanging the barrels and using a different cartridge as I changed barrels to that caliber.I like that feature, and I think it is of great importance in the military type of gun because the barrels wear out quite rapidly if they are fired rapidly and heat up, and they can be easily replaced in the field in this Johnson design.

Fred C. Ness承認了精度並沒有受影響,且可拆卸槍管是個優秀的設計。他也提及了約翰遜在精度方面優於M1:

I have a more limited experience with the Garand, I have personally fired only two of them, a total of a little over a thousand rounds, but the Garand did not equal the Johnson in accuracy.

隨後軍方的測試結果表明,約翰遜步槍在精度方面確實領先M1。

參與測試的四位射手都是經驗豐富的士兵:

- Harker, an outstanding rifleman and an outstanding rifle coach of 20 years service.

- 2.Gunnery Sgt. Claude N. Harris, recently the national rifle champion and one of the greatest rifle shots of the day, 12 years service.

- Platoon Sgt. Thurman E. Barrier, a distinguished rifleman and a distinguished pistol shot with a Nation-wide reputation as a marksman, and is, in addition, an expert in munitions; 8 years service.

- Platoon Sgt. Victor F. Brown, a distinguished rifleman and a distinguished pistol shot and highly experienced with the Ml rifle; 11 years service.

這次測試得出了以下結果

(1) The mechanical performance of all rifles was satisfactory.

(2) Ml rifle No. 3536 dropped its center of impact after 68 rounds 18 inches: after 112 rounds an additional 20 inches; a total shift of mean point of impact of 38 inches at 300 yards.

(3) Ml rifle No. 3729 shifted its center of impact 13 inches high after 71 rounds at 300 yards.

(4) Xo other shifts of center of impact were observed during the tests.

(5) Starting with an empty rifle, the average time from "commence firing" to the first shot fired was 5.5 seconds for the Ml and 11.8 seconds for the Johnson. The fastest loading time for the Johnson was 8 seconds, the slowest for the Ml was 10 seconds, first shots of each pair only being counted. Starting with loaded rifles, the normal situation in the field, the first shots were fired in equally fast time.

(6) The combined accuracy-rate of fire performance of the Johnson rifles was 9.9 percent superior to that of the Ml rifles.

除了精度方面的表現以外,約翰遜的作品還有另外的優勢,一旦考慮到軍隊要換裝半自動步槍,全自動步槍和輕機槍時,約翰遜已經為此準備了他的設計,她們將享有很高的生產性能。相當數量的零件時可以通用的。

(約翰遜先生設計的武器確實幫助菁英部隊很多,她們堅實耐用)

不可避免的,生產性也被再次提及。約翰遜步槍生產起來真的比加蘭德更麻煩?

按照底特律汽車產業和其他相關人士的介紹,生產約翰遜步槍一點也也不費事。

這裡我引用一些相關人士的對話

首先是GARDINER. C. B. Gardiner先生,來自Taft-Peirce Manufacturing Co(主力生產縫紉機的公司)

Early in March in 1938, Mr. Johnson brought to us a hand-made model of his rifle which he disassembled into its components, as he has done here before you, and asked us what steps we would recommend to put that—put such a rifle into production. We protested that that was a job for an arms manufacturer, that we had no experience whatsoever in the manufacture of firearms, and recommended that he take his problem to an arms manufacturer.

After a brief study of the mechanisms by our engineering staff, I quote from a report dated March 10, 1938, to me by our chief engineer, as follows:

I recommend the following procedure as the proper and most practical steps to take in preparing for production of approximately 50 rifles per day. That figure of 50 rifles was taken as an arbitrary figure. It can be expanded to any amount.

(起初我們是不願意的,我們不懂造軍火.jpg)

這一段是來自Kelsey-Hayes Co(一個造車輪的公司,工廠設於底特律和傑克遜)的代表,Perry Williams先生

We are mass producers of hydraulic brakes, passenger wheels, truck wheels, hubs and rims for the automotive industry,serving practically all of them.We have made a study of this, simply, purely, from a manufacturing standpoint. We arent gun manufacturers but we were impressed with the simplicity. We were also surprised at the generous tolerances allowed, in fact they are much more generous tolerances than we are used to working with with hydraulic cylinders, brakes, and that sort of thing. And we have gone at this more from pieces similar to what you see here. They are like parts we are making now, similar in production. And in our opinion this assembly could be tooled for in a comparatively short space of time, depending on obtaining what additional equipment or special equipment you might need, to produce 200 or 300 an hour very comfortably.

..... An hour. It is just a question of getting the equipment in. From our finding this barrel where it might be the slowest of the special equipment involved—but from my understanding there is barrel capacity in the country—we can produce at least 10,000 of these barrels a day. Because I understand they did produce that many when the war stopped before and that equipment must still be available. If it is not, it can soon be replaced if necessity demands it. As far as the study that has been made by Taft-Peirce, it is very thorough and it shows that they have designed and engineered this so it can be put in mass production with concerns such as our own or I would say in concerns similar to our own. There isnt any problem to it as far as that is concerned for manufacturing, it is all just parts that can be obtained and manufactured without much trouble and wewould be.....There is no technical difficulty at all. And I just came down here to state that we as an automotive accessory concern have examined it and would be willing to state that we could get in production in a very short space of time, in mass production. Just to give some idea of the ability of our company to manufacture and assemble machine-made products on a large scale on short notice, let me say that in Detroit the automotive trade consider 90 days a long time to tool up for a new product. After all that only leaves us about 9 months in which to do business, including working out the usual problems in any initial production run. These must be ironed out very speedily as you will appreciate when I tell you our daily production on some of our principal products.For example, we manufacture automobile and truck wheels at a rate of nearly 2,000 wheels per hour or 30,000 wheels per two-shift day—that means assembling 50,000 finished parts per hour or 750,000 finished parts per day as each wheel consists of about 25 individual pieces. For another example, we produce over 1,000 automobile hydraulic brake systems per hour or 18,000 per two-shift day—that means making and assembling over 120,000 parts per hour or 2,160,000 parts per day. We also manufacture 20,000 brake drums per day and 25,000 wheel hubs per day including heat treating and hardening of the same. We manufacture 16,000 tractor wheels per day, 800 tractor brakes per day, 800 tractor brake drums per day, and 5,000 miscellaneous automobile wheels per day. We employ 5,000 men per day in our United States plants alone. We also have plants in Canada and England. In closing, may I add that many of our manufacturing tolerances are kept within a thousandth to a half thousandth of an inch, which is much finer work than the Johnson rifle specifications call for.

這位來自汽車行業的先生也舉出了他供職的公司在汽車行業的生產情況:以每小時2000個或雙班日產30,000個的速度生產車輪,這意味著以每小時50,000個的速度組裝成品零件, 即每天組裝750,000個成品零件;他們還可以以每小時1000個或雙班日產18000個的速度生產汽車液壓制動系統,這也意味著以每小時120,000個,即每天2,160,000個的速度組裝這樣的成品....(略過一堆產能描述)。僅在美國的工廠,這家公司每天就有5000名僱工在工作,在加拿大和英國她有工廠。最重要的是,他們生產汽車零件所要求的公差元高於約翰遜半自動步槍所要求的。

唯一的問題就是槍管產量**

*美國上個世紀30年代-40年代的工業實力真的錘爆了233,這還只是一家公司

**這一點稍後會繼續提到,

第三段描述是來自Sparks-Withington Co的總裁:William Sparks(他們有在上一次大戰中生產軍備的經驗)

I feel possibly that I may have been called on to tell what I think about this job as a mass production job and so that I might qualify as knowing something about mass production I think it might be of interest to you to know that our company at the present time in. 2 of its 6 plants are producing 16,000 automobile hours per day. Each one of those horns represents 175 pieces. This rifle represents 103. That necessitates that we must do a total of operations on horns each month of 95,040,000 operations. During the last war we produced 2,000 75-millimeter shells per day, 9,000 helmets per day, 72,000 hand grenades a day.

Now then I hope that qualifies me as a mass-production person. We want to say that we have examined this rifle and this is no more difficult to produce than lots of things that we have done before and are doing today. I quite concur with Mr. Williams of Kelsey-Hayes. Any questions?....We would get into production within 6 months at the rate of 1,000 a day

簡單描述了一下他們過去的經驗,並給出了可以在六個月內準備好投產,日產量1000支的答覆。

第四段描述來自Hupmobile Motor Co的總裁. Walter Drake和所屬首席工程師Mr. Scott(scott這名字好熟悉啊233)

Well I have only a few brief words to say about this project, Mr. Chairman. I am here with Mr. Scott our manufacturing manager, who might be glad if you would call for a brief statement after I have finished. I have gone over the mechanism of the rifle and these pieces that are lying on the table. I am not an engineer but a motor car executive. I am very familiar with this type of work and have had off and on about 30 years experience in the motor industry building the Hupmobile car, and, in my opinion and that of Mr. Scott who will tell you in a little different way, these parts here of the Johnson rifle are no more difficult to make true to specifications, in fact are easier than the machine work that we have been doing for 30 years in building the engine power plants, axles, and other parts of our car.

I might give you an illustration and I would ask Mr. Gardiner to check me if I make a misstatement about tolerance, the tolerances, that you are allowed one way and another in making these parts. They are considerably freer than we are held down to in making parts for a motor car. If we were to build a Hupmobile engine with as much as three one-thousandths in some of the parts like the moving parts inside the engine, gentlemen, you would take it back and say, "Give me a good engine, this rattles too much." We cant do that. We have to have it done sometimes to as much as half a thousandth, as these gentlemen who are familiar with these mechanical matters know. There are no problems in the manufacture of these Johnson rifles so far as the manufacture of these parts is concerned that should trouble us in the least after our experience or, as Cap tin Sparks said, in a factory like his. As to production I would agree with him that it is entirely feasible to get up to production of a thousand per day within 6 months. There is nothing about it that would present any great problem along that line. But I dont want in any manner of means anything I have said to be useo1 as an inference that I know anything about making guns or am I a gun maker. I wouldnt consider this a gun makers problem, as it is purely a machine tool and tool-making proposition. I would be glad to answer any questions but I would be much more pleased if you would like to ask Mr. Scott something particularly here because he has had 30 years experience in practical shop machine tooling, and I asked him to come down.

總裁說了這樣一句話:I wouldnt consider this a gun makers problem, as it is purely a machine tool and tool-making proposition.我不認為這是一個槍支生產商的問題,這只是一個機床和工具製造的問題。

接下來是首席工程師,Mr. Scott的記錄,這是一位有著30年經驗的工程師。

To give you a brief outline of my experience, I have been building motor cars, trucks, engines, and parts in automobile and truck manufacture the past 30 years, particularly in the production line. I had an opportunity to look this gun over on two different occasions and we have submitted it to our engineers and also to our production departments and we also see no production problems. We dont mean to say that it is going to be a run-away cinch but it is just a problem for manufacturers to work out that can be worked out and can be worked out readily. As far as mass production on this gun is concerned it depends entirely on your tooling, you can tool to do 50 a day or a 1,000 a day, or any other number you wish.

... As stated by Mr. Drake, the limits on this gun are far in excess of the limits on many parts we make...I would think that we had in the Hupp organization the major portion of the tools. There is some of this boring equipment that if we were to make the barrel we would have to procure.The raw materials as I understand it as far as I have gone into this gun, any of the materials that go into the manufacture of this gun can be procured from any well stocked steel supply house. There are no special analyses that we have been able to find required for this gun, and it would seem to me that all the steels could be obtained readily....

....They buy the steels from the mill and they hold them on hand for the convenience of their customers. For instance the Ryerson Co. in Detroit and others besides carry large stocks of all kinds of steels.

提到了一個生產問題,槍管製造需要購買額外的設備。但他也指出,原材料並沒有什麼特別之處,都可以輕鬆獲得。Scott先生也十分了解鋼材市場的情況,他知道從那可以購入合適的原材料。

約翰遜先生自己也聲稱他盡量他的貝姬很適合汽車行業生產(通常來說,這裡有personal bias之類的)

We have tried to bring out that the weapons can be made easily, that it isnt a strange and unusual piece of work which requires special operations, but instead is capable of being adapted to the automotive industry, which has been pretty well represented here at this meeting by these gentlemen.

之後也有一張來自Mr. J. E. Owsley的信件(High Standard Co有在生產武器,這個時間他們也在生產機槍)

除了投入生產的描述外,還有最重要的一句話:

Four Johnsons can be made to one Garand and at about half the price under high pressure production.

可以用一支加蘭德一半的價格生產四支約翰遜

到這裡,我想約翰遜步槍的生產性已經有了足夠的解釋。顯然,約翰遜在這方面比加蘭德更加優秀。

這時候我們再來看看加蘭德的生產商有那些(我懷疑三等人是不是和某些廠有py)

那末,我們再回到約翰遜步槍和加蘭德的對比,約翰遜步槍真的有那麼多零件嗎?

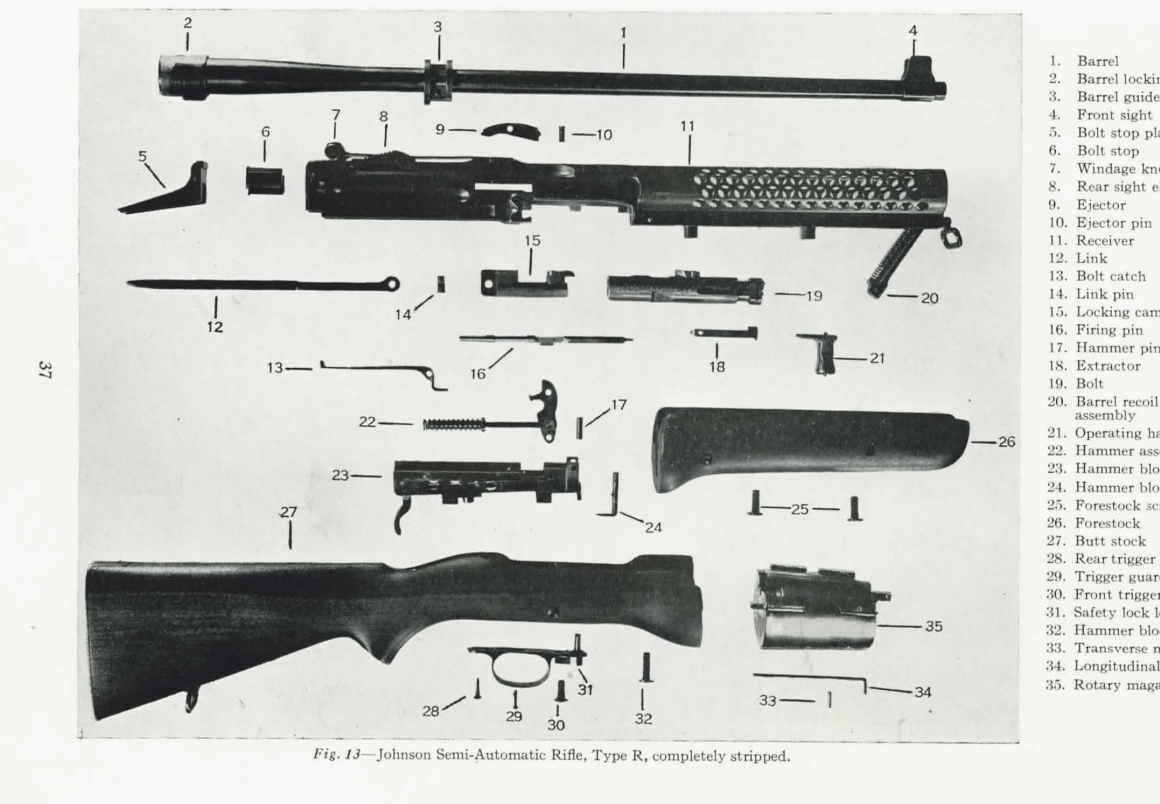

事實顯然不是,即使在完全拆解的情況下,約翰遜步槍(Type-R)也只有35個零件,遠遠少於加蘭德步槍。同時,我上面也提到過,約翰遜步槍可以在30秒內完成對槍管的更換(9)。

拆解有不完全和完全拆解兩種,就算是比完全拆解約翰遜步槍的零件也比加蘭德少的多得多。

至於上油費事這個,暫且不說這是哪裡來的結論,又或者是什麼原因導致這一款只有35個零件的槍保養費事(有來源的話請回復)。在實際測試中不上油的槍依舊可以正常發射1500發子彈,在此過程中沒有出現任何故障。

還有這麼幾張圖

「互聯網上有這麼一批人,自身文化素質低,看不懂(或者看不進去)正兒八經的檔案、專著、論文,又沒有積極上進、好好學習的態度,不過是看了幾篇不著四六的網文,便自以為發現了歷史「真相」,到處複製粘貼,成天自鳴得意上躥下跳。」

總結

我就不再自己重複了,我已經發現了一個很好的,很適合作為總結。其實這已經回答了約翰遜步槍和M1的優劣,與之相比我的文章只能是臃腫不堪的拼湊。

只要你們看完這些,就會發現網路上長久以來圍繞約翰遜和加蘭德的對比都是有嚴重錯誤的。

無論如何,約翰遜半自動步槍是一款比加蘭德優秀的武器

我也產生了另外的疑問,陸軍真的認識到約翰遜沒一樣比得過加蘭德?是不是三等人做了什麼py交易?

終

這只是我出於個人興趣整理二次大戰時USMC二次大戰期間裝備時無意發現的一些內容,我們知道事實是約翰遜半自動步槍沒有競爭過加蘭德。但作為YAG Corps 所屬檔案管理部門(迫真),我希望了解約翰遜步槍是否真的在性能,生產性上落後於加蘭德,馬潤是否真的會選擇一種完全不如M1的「次品」來滿足自己的需要,遂將其簡單整理。由於本人水平所限,對槍械也無所了解,最終成果是這一篇簡陋,粗糙的文章。像以往戰車相關文章那樣為提供大量配圖和細節描述,對我來說還是過於困難。

我唯一能做的就是盡量提供原文讓諸位觀看,這也是我的水平所限。現在大部分關於武器的介紹都是一種翻譯作品,我是說罕有新發現,同樣的內容能夠在變換文字之後重複的展現,這樣寫出來的東西終究是無意義的,比復讀機高明不了多少。來自過去時代的文本是有限的,他們甚至還在減少,我們要做的應該是去努力發掘,讓更多的信息得到整理並加以利用。文中所引終究是在約翰遜得以為USMC大規模生產前,這有部分可能是生產商為了爭取訂單而誇大的描述。遺憾的是,約翰遜步槍從未真正的像其他主要武器那樣以戰時規格進行大規模生產,我們無法真正的將這一項與加蘭德進行比較。希望以後會有人來完善相關的內容,這也是我以後想要做到的,更多有關約翰遜步槍的文件和小冊子正在整理,也會有後續文章(JSR in Action系列)。現在,就像文章開頭所說的一樣,請諸位慷慨的指出文章內的錯誤。

最後,也要感謝出鏡的各位老婆和未婚妻,我對你們的愛都是一樣的,和胸部大小無關。

期待早一點能在窯子里見到貝姬。

source:

1. We have at the present time, as a result of the past general feeling of the American people, I think it is fair to say, perhaps an inadequate amount of war equipment. I may be usurping my prerogative, if I have any, to say that it is my conviction that if there is any blame to be attached for that, it is to be attached to the people of the United States, who, like the people of England, did not wish to have any army, were not willing to pay the price that was necessary to maintain an army, were not willing to provide funds for the often necessarily extensive experimentation and trial of military inventions. Now we have, with regard to rifles, as I understand it, we have a large number of the relics of the World War, Enfields and Springfields. I understand that there are approximately two million caliber .30 rifles of the two types, Enfield and Springfield, which are in reserve. It has been admitted that we would have to use those rifles at the beginning of another emergency. Those rifles use the same ammunition, caliber .30, Ml or M2 or Ml906. Both of those rifles load with Springfield clips, a 5-shot brass clip or a charger from which the cartridges are stripped into the magazine. So far as I am aware, most of the other United States caliber .30 weapons and certain of their accessories are well adapted to the use of that clip. For example, the loading machine that is used on the Browning machine gun M1917, I believe is adapted to the use of that clip to strip cartridges to be loaded into the belt.

Now, to refer for the first time specifically to the Johnson semi- automatic rifle, in that connection the Johnson rifle was particularly designed during 1938 and 1939 to be adapted to the Springfield-type clip. tjsr P3

2. That is a technical matter, and there are certain criticisms of the Springfield-type clip, but I do want to state here that I think we must take into consideration the fact that we have those two million rifles already which load with that clip, and that it is certainly an advantage of the Johnson rifle that it is adapted to the Springfield clip. tjsr P3

3(忘記在哪一頁了)

4 (上同)

5(上同)

6(上同)

7(上同)

9 見文末第一個視頻,在附帶解說的情況下拆卸槍管只需14秒

題圖:https://usmcweaponry.files.wordpress.com/2016/10/img_25343.jpg?w=940

約翰遜步槍完全拆解來自約翰遜步槍操作手冊(和以往一樣,我上傳到書館和群里了)

加蘭德步槍完全拆解(這是一個很好的網站):https://www.thefirearmblog.com/blog/wp-content/uploads/2013/11/Anatomy-Rifle-M1-Garand.jpg

B站上有人搬了兩個視頻(看起來比較方便)

- 這個裡面推薦看一下槍管的部分

【輕兵器Enthusiast】美國約翰遜m1941半自動步槍試射(TFB TV)_嗶哩嗶哩 (゜-゜)つロ 乾杯~-bilibili

2. 這個裡面有關於裝填的部分

【被遺忘的武器】美國約翰遜M1941半自動步槍射擊_嗶哩嗶哩 (゜-゜)つロ 乾杯~-bilibili

下期預告:

Armr 3 舌尖上的阿媽

Hunt: Showdown 獵魔故事中的武器

the Hunter?: Call of the Wild 霰彈槍使用指南

以及可能的福利(某〇的416還真好看,)

推薦閱讀:

※如果真上戰場,大家會選擇什麼樣的槍械

※第91期:《火柴槍悲劇還在上演,提高槍支認定標準刻不容緩》

※美國陸軍CSASS簡史

※槍械的供彈